Bases for sheet metal rolling machines

Holzmann and Bernardo sheet metal rolling machine bases: an essential accessory for your precision work

Holzmann and Bernardo sheet metal rolling machines are essential tools for professionals and metalworking enthusiasts. They allow you to produce precise rolling and shapes from metal sheets. To maximize their performance and ensure optimal work, choosing a suitable base is essential.

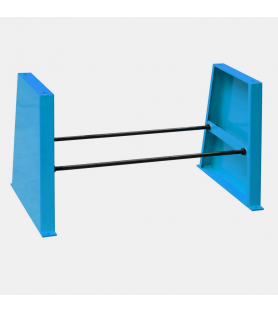

A sheet metal rolling machine base plays a fundamental role in the stability and efficiency of the equipment. It provides a solid base that absorbs the vibrations generated by the machine during rolling. This not only allows for greater precision in the work, but also extends the life of the rolling machine by reducing wear on mechanical components.

Manufacturers Holzmann and Bernardo, renowned for the quality of their equipment, offer bases specifically designed to fit their rolling machine models. These bases, often made of sturdy steel, guarantee a high load capacity while remaining compact to easily integrate into restricted work spaces. Their ergonomic design ensures a comfortable working position, which is an asset for professionals who have to use the machine for long hours.

In addition to their robustness, these bases are distinguished by their modularity. Some models are equipped with quick fixing systems or height adjustments, allowing the position of the rolling machine to be adjusted according to the specific needs of the user. Others integrate casters or handles to facilitate the movement of the assembly in the workshop.

By choosing a suitable base for your Holzmann or Bernardo rolling machine, you are investing in the performance, safety and longevity of your equipment. This small accessory makes all the difference in the realization of your metallurgical projects, whether it is one-off work or more intensive production. Do not neglect it to optimize your results!

Base for the Holzmann BBM1000 sheet rolling machine

Base for the manual sheet machine Holzmann BBM1000.

Base for Holzmann UBM760 or Bernardo 3 in 1 bending machine in 760 mm

Stand for thread rolling machine, brake and shear

Base for Holzmann UBM1400 or Bernardo 3 in 1 rolling machine in 1320 mm

Base for machine Holzmann UBM1400

Base for manual shears Bernardo PTS650S

Base suitable for the Bernardo PTS650S manual shears