Shafts and bushings

Wide range of quality shafts and bushings at Probois Machinoutils!

Shafts and bushings for metal lathes, drill-mills and drill presses are essential elements in precision machining. These components are used to fix and hold cutting tools, chucks or drills in place, thus ensuring smooth and precise operation of machine tools. Different types of shafts and bushings are available, each with characteristics adapted to specific applications in the field of metal machining. Among the most commonly used elements are reduction bushings, increase bushings and chuck holder shafts.

Reduction and increase bushings

Reduction bushings are components that reduce the diameter of a shaft or chuck to make it compatible with a tool or machine with a smaller fixing capacity. They are widely used in metal lathes, drill-mills and drill presses to adapt a tool to a larger shaft. For example, a reducing sleeve can be used to mount a small diameter chuck on a larger diameter shaft, allowing the use of smaller accessories while maintaining the stability and safety of the tool.

Increasing sleeves, on the other hand, have the opposite effect: they allow the diameter of an shaft to be increased so that it can be used with larger diameter tools or chucks. These sleeves are particularly useful for adapting standardized tools to more specific machines, or for increasing the working capacity of certain drills or milling machines.

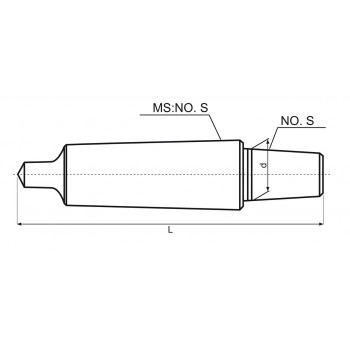

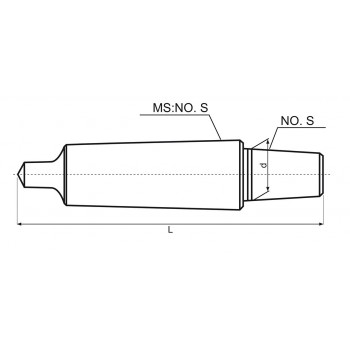

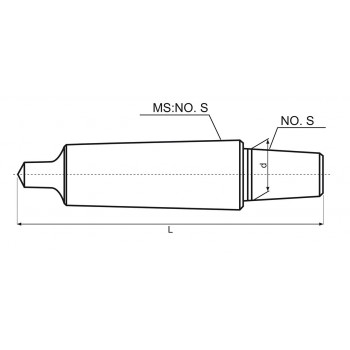

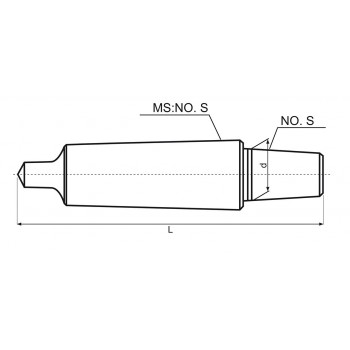

Chuck holder shaft

Chuck holder shafts are essential machining parts that are used to fix chucks to machines. These shafts are used in many applications, including metal lathes and drill/mill machines, and are used to hold chucks in place while ensuring stable operation. A chuck holder shaft is often designed to withstand high forces, especially when the chuck rotates rapidly. These shafts are made of strong, durable materials, such as hardened steel, to ensure long life and high accuracy in drilling and milling work.

Using the right shaft and bushings is crucial to ensuring the accuracy and safety of machine tool operations. A poor quality reducing or increasing bushing can cause vibration, positioning errors and premature wear of parts, which can affect the quality of work and the life of equipment. It is therefore essential to choose shafts and bushings made of high-quality materials and adapted to the specifications of the machines.

Practical applications

In a metal lathe, for example, a chuck shaft is used to hold the cutting tools in place, allowing for precise and efficient turning operations. On a drill-mill, the use of reduction sleeves allows for mounting small diameter cutters on a larger shaft, thus providing greater flexibility in the choice of tools. In a drill press, increase sleeves allow working with larger chucks to produce large diameter holes, while maintaining optimum stability and precision.

Conclusion

shafts and bushings are essential elements that contribute to the flexibility and precision of machine tools. Depending on the specific needs of users, there is a wide range of reduction sleeves, increase sleeves and chuck shaft, allowing tools and machines to be adapted to various applications. Choosing the right components not only ensures high-quality results, but also improved safety and increased equipment longevity.