-

MenuBack

-

Wood and Metalworking Machines

-

-

Woodworking Machines

- Sharpener

- Dust collector

- Wet and dry vacuum cleaners

- Combination woodworking machine

- Table router

- Planer and thicknesser machines

- Planer and thicknesser machines

- Surface planer

- Thicknesser

- Power feeder

- Mortisers

- Blum and Grass Hinge Drill

- Edge banding machine

- Sanding machine

- Sanding downdraft table

- Scroll saw

- Sliding mitre saw

- Band saws

- Table saw

- Spindle moulder and spindle moulder-saw

- Wood lathe

-

-

-

Metal working machines

- Tools and accessories

- Abrasive and sanding accessories

- Drill chuck arbor and morse taper

- Coolant device and fluid

- Power feed and rotary table

- Knives for hand shears

- Vises

- Band saw blade

- Follow and steady rest

- Drill chuck

- Independant chuck and live center

- Milling tools

- Turning tools and accessories

- Mill chuck and collets

- Stand for metal machine

- Metal Drill Grinding Machines

- Metal Dust Collector

- Deburring and chamfering machine

- Tools and accessories

-

-

-

-

-

Woodworking tools

-

-

-

Saw blades

- TCT Scoring

- TCT Circular Saw Blade

- Circular saw blade Ø 120 mm to 150 mm

- Circular saw blade Ø 160 mm and special Festo

- Circular Saw Blade Ø 165 Mm

- Circular Saw Blade Ø 180 Mm

- Circular Saw Blade Ø 190 Mm

- Circular saw blade Ø 200 mm

- Circular saw blade Ø 210 to 220 mm

- Circular saw blade Ø 230 to 240 mm

-

- Circular saw blade Ø 260 to 270 mm

- Circular saw blade Ø 300 mm

- Circular saw blade Ø 303 to 315 mm

- Circular saw blade Ø 350 to 355 mm

- Circular saw blade Ø 400 à 700 mm

- Rings Of Reduction For Blades

- Blade Saws Logs

- Bandsaw blade

- Bandsaw Blade 1050 To 1425 Mm

- Bandsaw Blade 1490 To 1610 Mm

- Bandsaw Blade 1712 To 1875 Mm

- Bandsaw Blade 2100 To 2180 Mm

- Bandsaw Blade 2215 To 2240 Mm

- BandSaw Blade 2300 To 2360 Mm

- Bandsaw Blade 2400 To 2630 Mm

- Bandsaw Blade 2760 To 2950 Mm

- Bandsaw Blade 3330 To 3380 Mm

- Bandsaw Blade 3430 To 3500 Mm

- Bandsaw Blade 3600 To 3865 Mm

- Bandsaw Blade 4013 To 4230 Mm

- Bandsaw Blade 4424 To 5611 Mm

- Saw Blade Scroll Saw

- Blade Jig Saw

-

-

-

-

-

-

-

Metal Tools

-

-

Accessories

-

-

-

-

-

-

-

Accessories for spindle moulder

-

MAINTENANCE OF WOOD

-

Other tools

-

-

- Workshop equipment

-

Spare parts

-

-

-

-

-

-

PAR FAMILLE DE PRODUITS COMMUNS

-

-

Quincaillerie

-

- Promos

-

- Abrasive belt for metal sanders

- Shafts and bushings

- Coolant device and fluid

- Tailstock for metal lathe

- Power feed and rotary table

- Shear knives

- Metal band saw blades

- Vises

- Metal lathe steady rests

- Metal measuring tools

- Wheels for twist drill sharpener

- Chucks for metal lathe

- Drill chuck

- Metal lathe tools

- Inserts for metal lathe tools

- Mounting plate & flange for metal lathe

- Quick change tool holder for metal lathe

- Milling tools

- Mill chuck and collets

- Roller and brush for renovation sander or resurfacer

- Metal machine bases

- Base for metal lathe

- Milling head for metal lathe

Tools and accessories for metal machines

Filter By

Price

Price

-

€11.00 - €13.00

Availability

Availability

Special Products

Special Products

Shafts and bushings

Wide range of quality shafts and bushings at Probois Machinoutils!

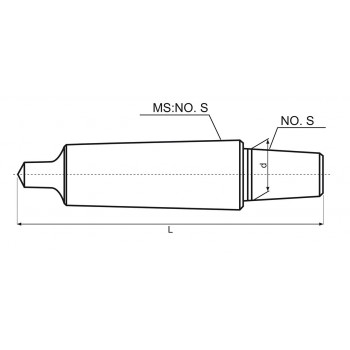

Shafts and bushings for metal lathes, drill-mills and drill presses are essential elements in precision machining. These components are used to fix and hold cutting tools, chucks or drills in place, thus ensuring smooth and precise operation of machine tools. Different types of shafts and bushings are available, each with characteristics adapted to specific applications in the field of metal machining. Among the most commonly used elements are reduction bushings, increase bushings and chuck holder shafts.

Reduction and increase bushings

Reduction bushings are components that reduce the diameter of a shaft or chuck to make it compatible with a tool or machine with a smaller fixing capacity. They are widely used in metal lathes, drill-mills and drill presses to adapt a tool to a larger shaft. For example, a reducing sleeve can be used to mount a small diameter chuck on a larger diameter shaft, allowing the use of smaller accessories while maintaining the stability and safety of the tool.

Increasing sleeves, on the other hand, have the opposite effect: they allow the diameter of an shaft to be increased so that it can be used with larger diameter tools or chucks. These sleeves are particularly useful for adapting standardized tools to more specific machines, or for increasing the working capacity of certain drills or milling machines.

Chuck holder shaft

Chuck holder shafts are essential machining parts that are used to fix chucks to machines. These shafts are used in many applications, including metal lathes and drill/mill machines, and are used to hold chucks in place while ensuring stable operation. A chuck holder shaft is often designed to withstand high forces, especially when the chuck rotates rapidly. These shafts are made of strong, durable materials, such as hardened steel, to ensure long life and high accuracy in drilling and milling work.

Using the right shaft and bushings is crucial to ensuring the accuracy and safety of machine tool operations. A poor quality reducing or increasing bushing can cause vibration, positioning errors and premature wear of parts, which can affect the quality of work and the life of equipment. It is therefore essential to choose shafts and bushings made of high-quality materials and adapted to the specifications of the machines.

Practical applications

In a metal lathe, for example, a chuck shaft is used to hold the cutting tools in place, allowing for precise and efficient turning operations. On a drill-mill, the use of reduction sleeves allows for mounting small diameter cutters on a larger shaft, thus providing greater flexibility in the choice of tools. In a drill press, increase sleeves allow working with larger chucks to produce large diameter holes, while maintaining optimum stability and precision.

Conclusion

shafts and bushings are essential elements that contribute to the flexibility and precision of machine tools. Depending on the specific needs of users, there is a wide range of reduction sleeves, increase sleeves and chuck shaft, allowing tools and machines to be adapted to various applications. Choosing the right components not only ensures high-quality results, but also improved safety and increased equipment longevity.

There is 1 product.

Active filters

- Availability: Not available