Including €2.80 for ecotax

Reference: MBORING21

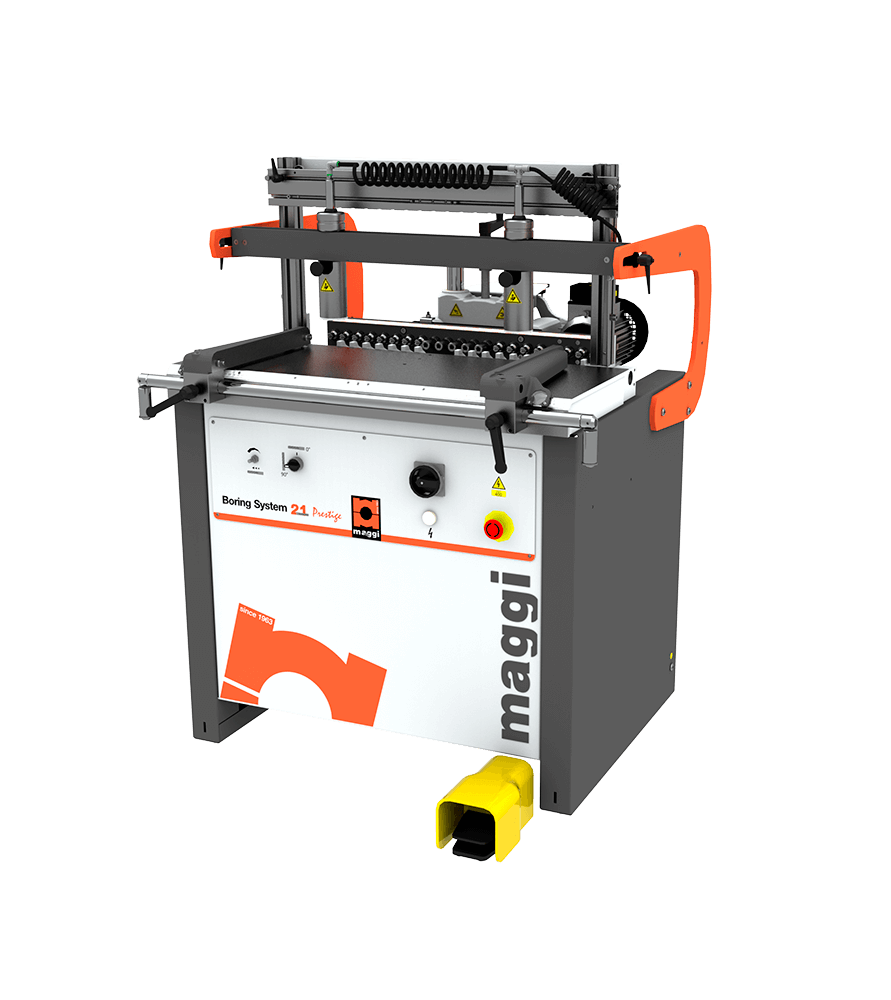

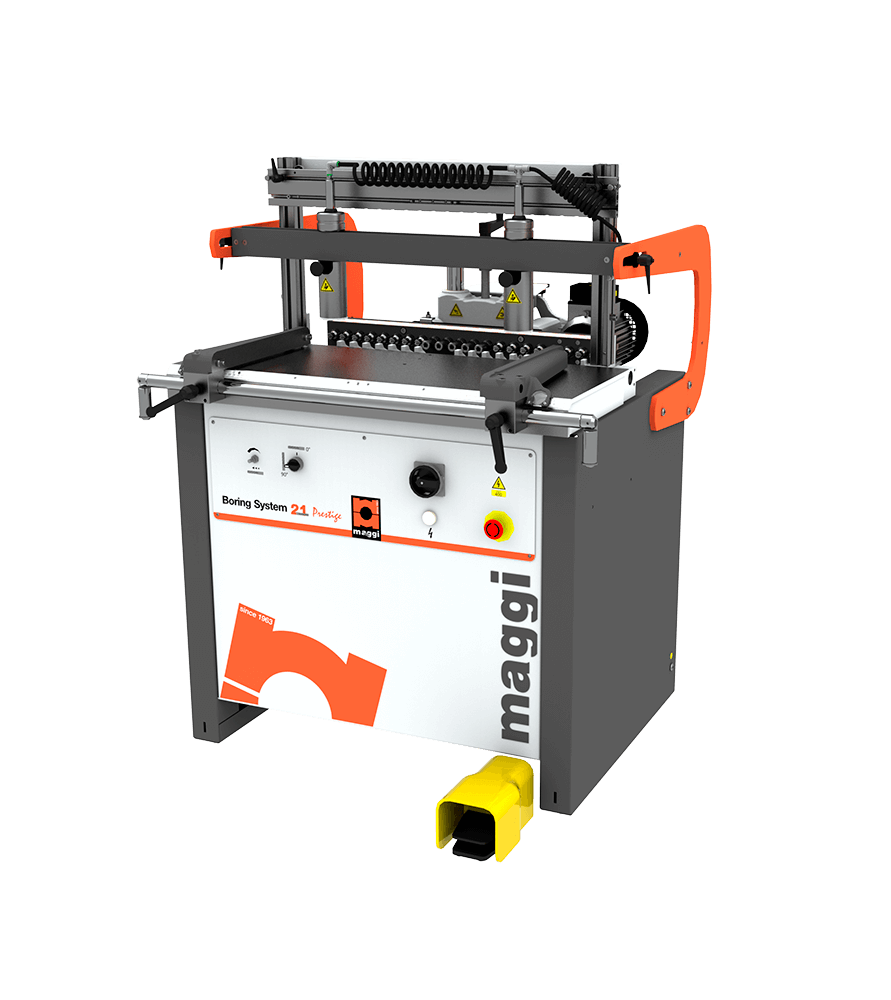

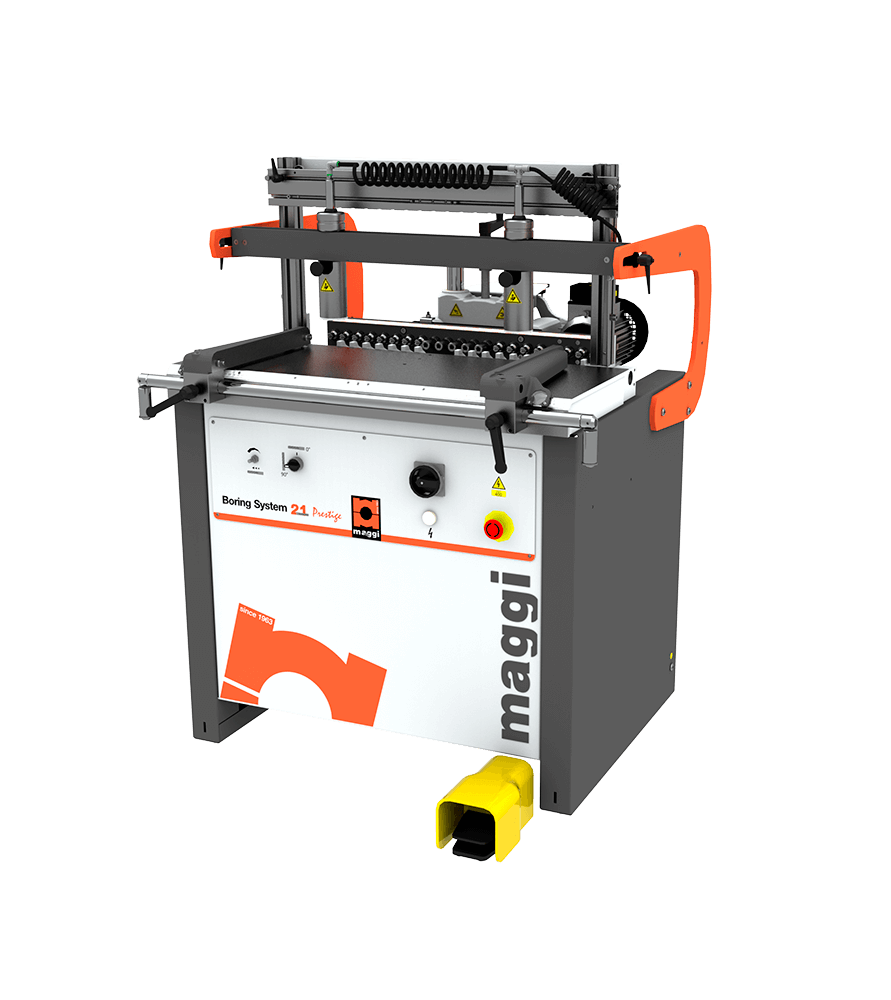

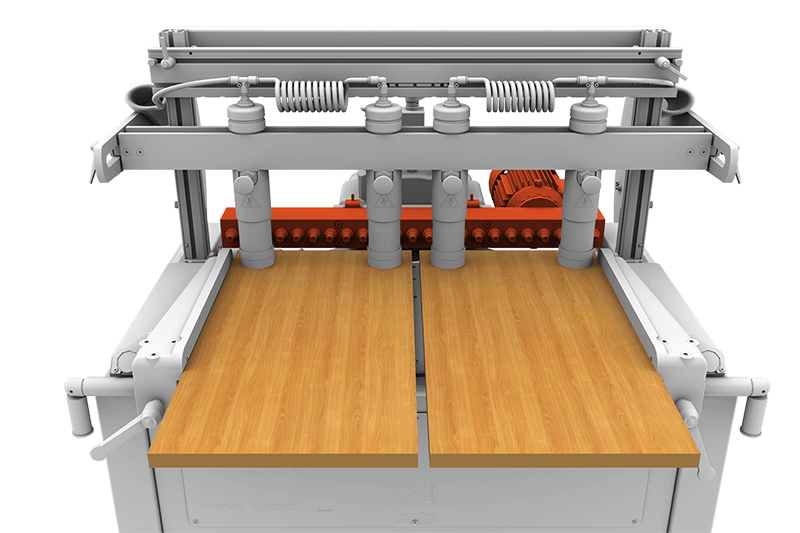

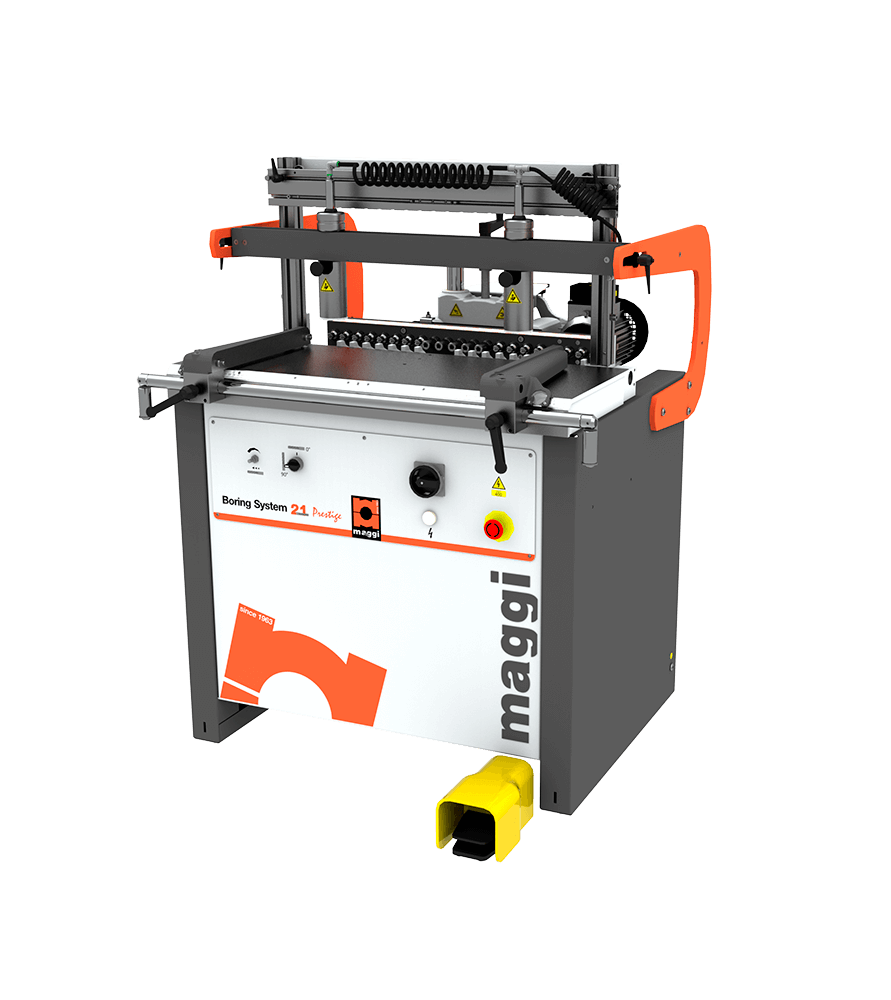

Semiautomatic, multispindle, single-head boring machine Maggi 21 PRESTIGE

Totally secure payment!

Totally secure payment!

Be delivered where you want!

Be delivered where you want!

14 days to change your mind!

14 days to change your mind!

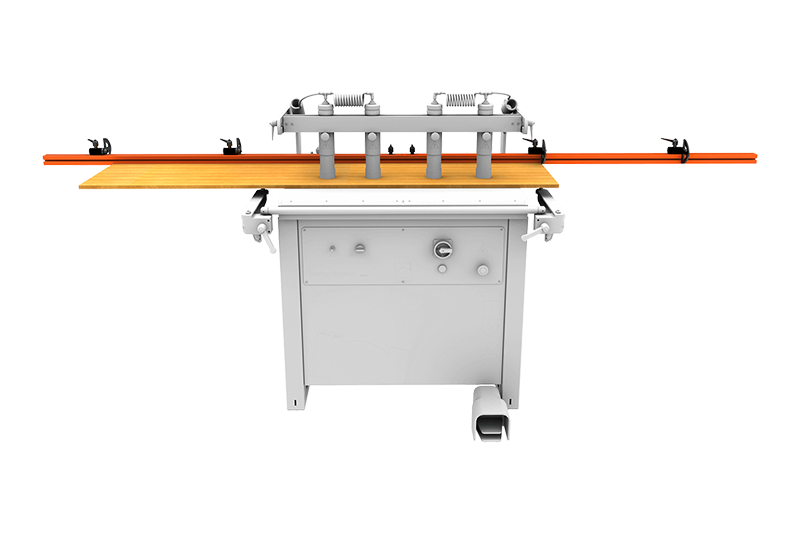

This compact machine is designed to work on panels and solid wood, all types of furniture.

FAST HORIZONTAL DRILLING

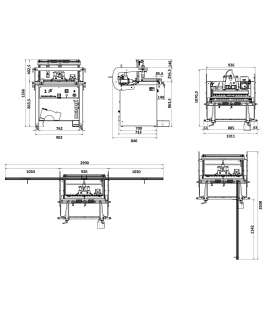

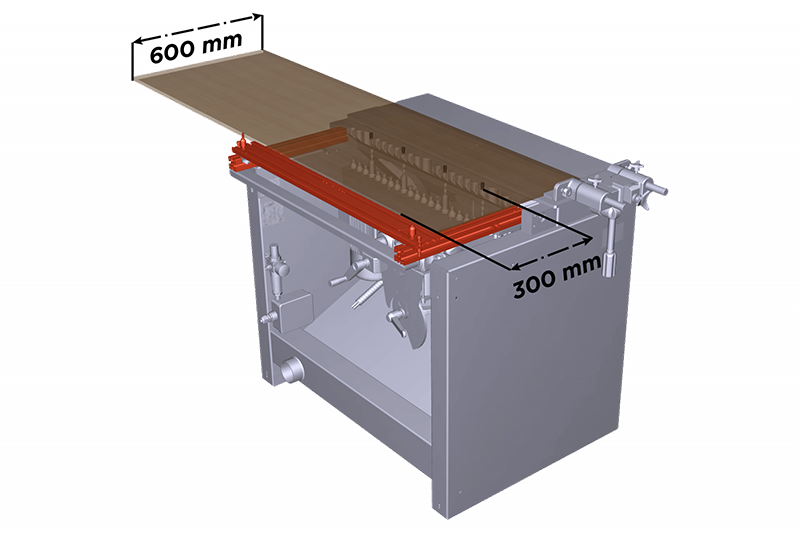

Thanks to the 640 mm interaxis and the large working table, You can process 2 panels having 316 mm width at the same time.

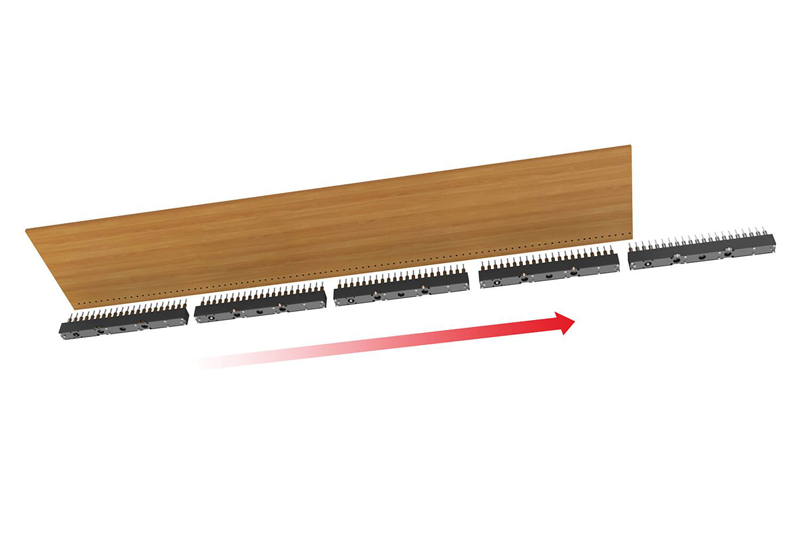

FAST VERTICAL DRILLING

You can process 3000 mm - long sides in 5 working cycles.

PERFECT PANEL JOINTS

The ref. side fences, adjustable along a metric bar, with magnify glass and nonius , always represent a precise reference point for the operator and guarantee the perfect parallelism of the drilling operations.

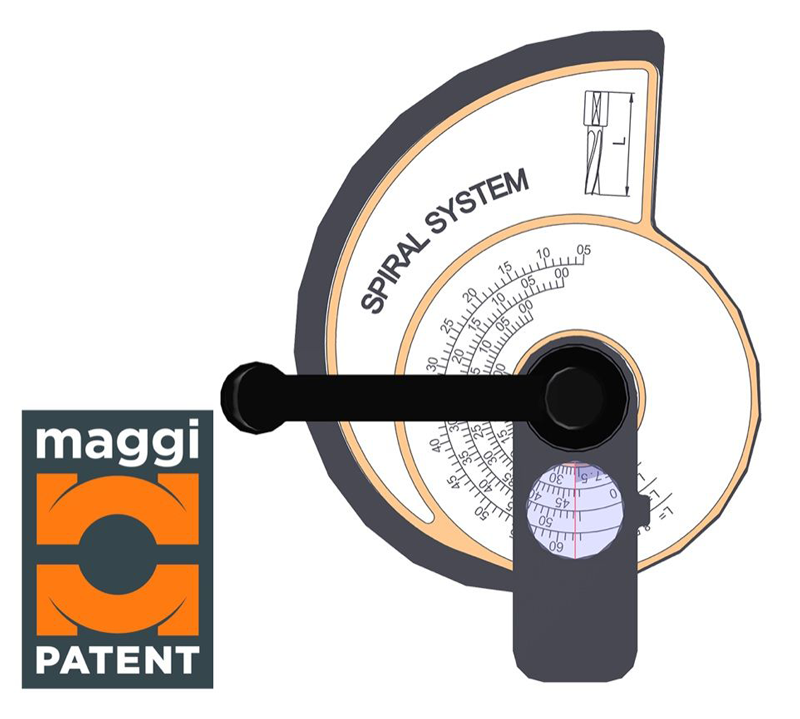

QUICK SET-UP

Adjusting the boring depth is extremely easy with the "Spyral System" device and the 10 mm automatic reset for vertical drilling.

VERSATILITY

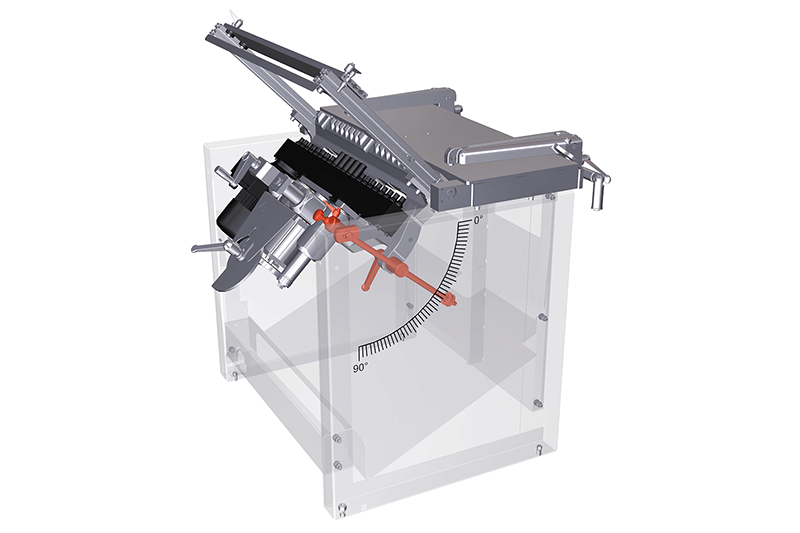

It drills at any angle between 0° and 90°.

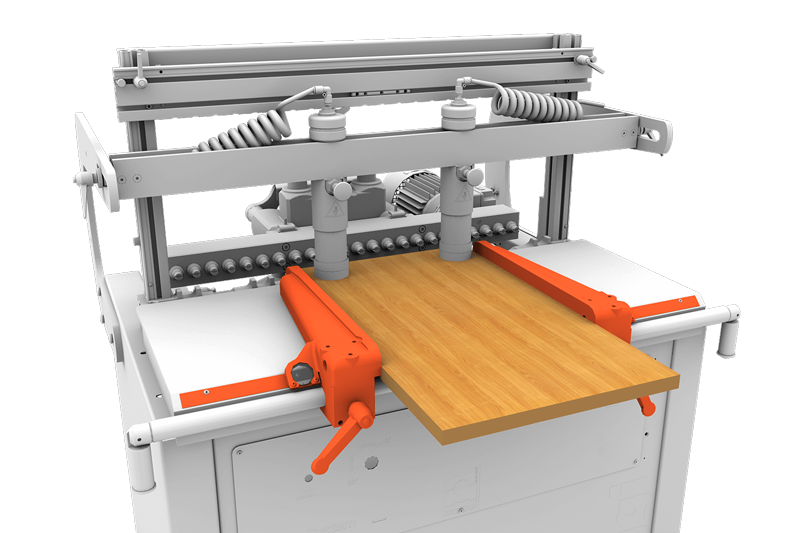

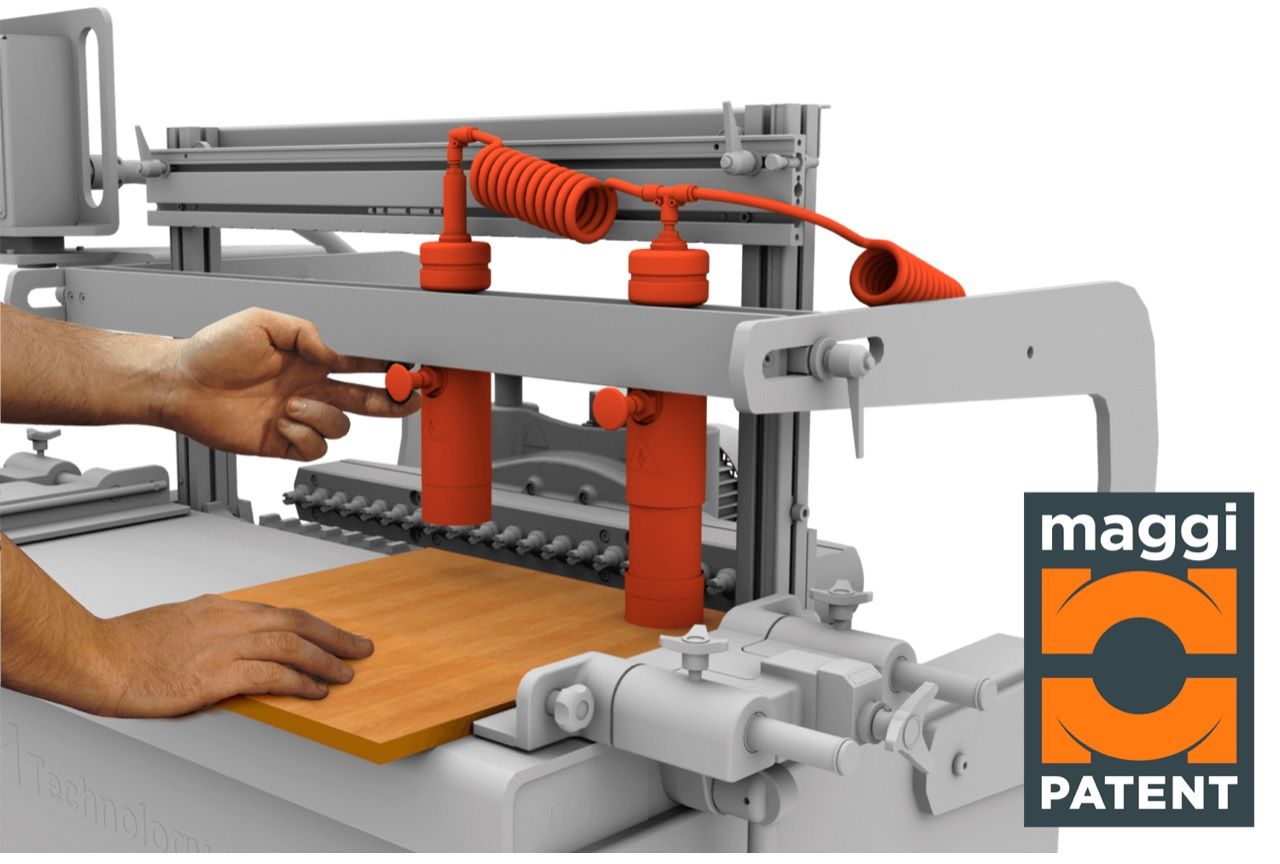

SAFE PANEL HOLD-DOWN

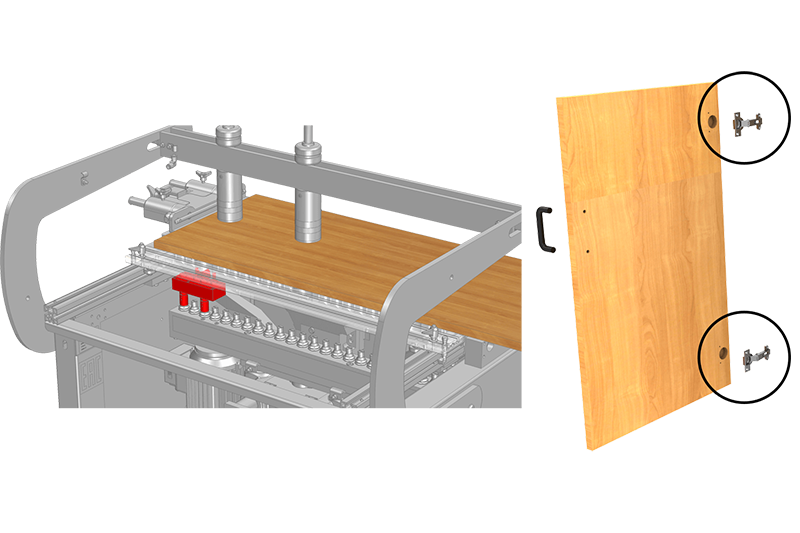

The quick-positioning, safety, hold-down clamping units ensure the greatest stability and steadiness of the working piece during the working cycle and the highest accuracy of the drilling process.

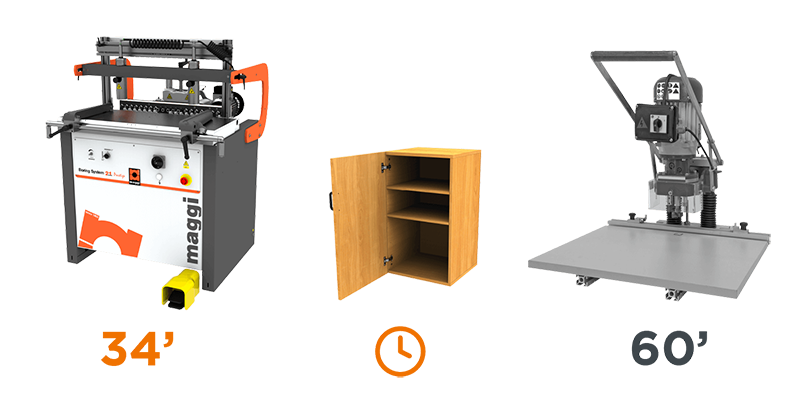

PRODUCTIVITY

Two times faster than a bench top boring machine.

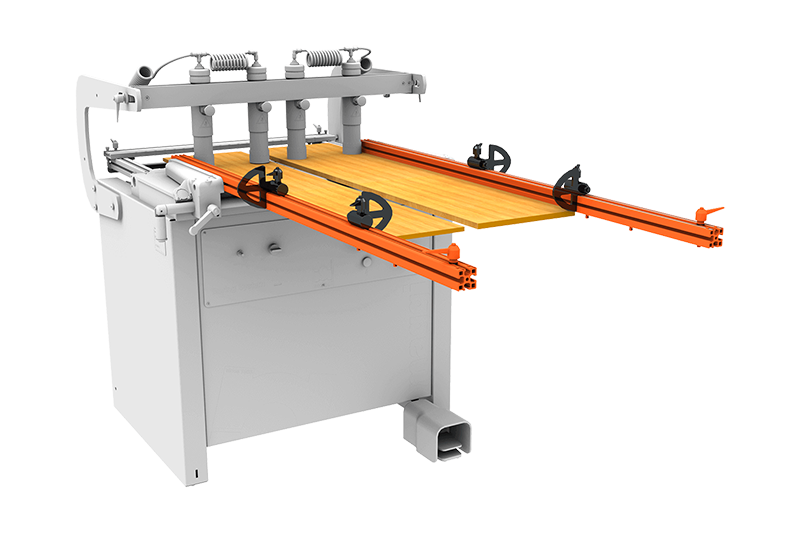

QUICK AND ACCURATE PANEL POSITIONING

Thanks to the two aluminium fences 1500x 80 mm with 4 reference stops, (two are included, two are options).

REAR FENCE

The rear fence, 300 mm stroke, allows to drill holes right in the middle of wardrobe side-panels, without using the long fence.

FIXED STOP FOR HINGES

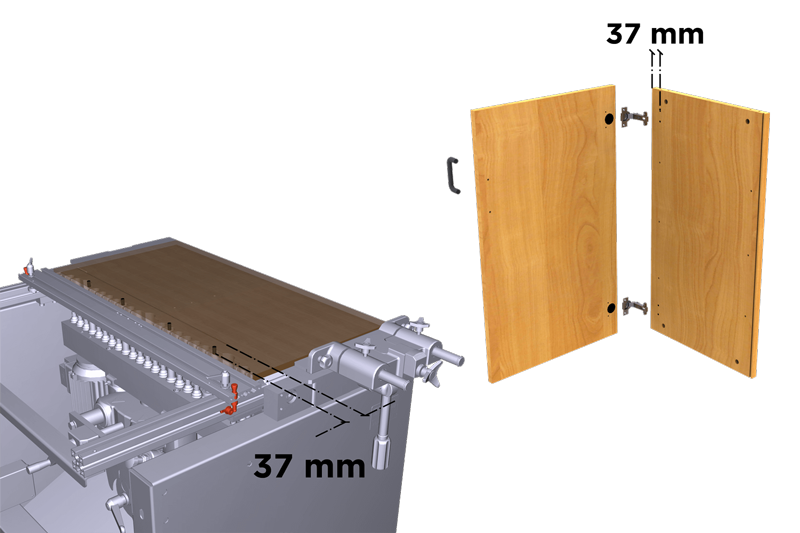

The 37 mm fixed ref. stop is extremely useful to drill fixing holes for the hinges on side panels.

SOLID STRUCTURE

Made of steel, built to last, eco-friendly, rust-resistant powder coating. Boring head is made of aluminium, while internal gears are made of rectified steel.

QUICK AND ACCURATE PANEL POSITIONING

Thanks to the two aluminium fences 1500x 80 mm with 4 reference stops, (two are included, two are options).

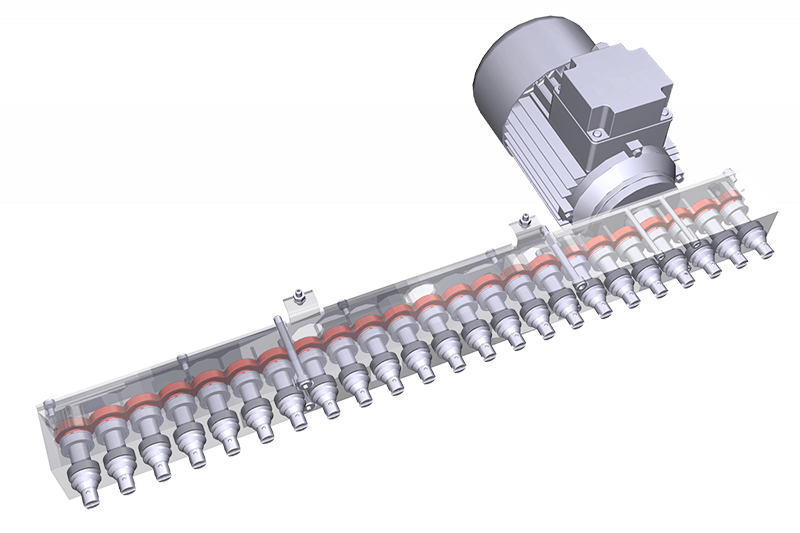

SPECIAL DESIGN TO WORK WITH LARGE-DIAMETER DRILL-BITS

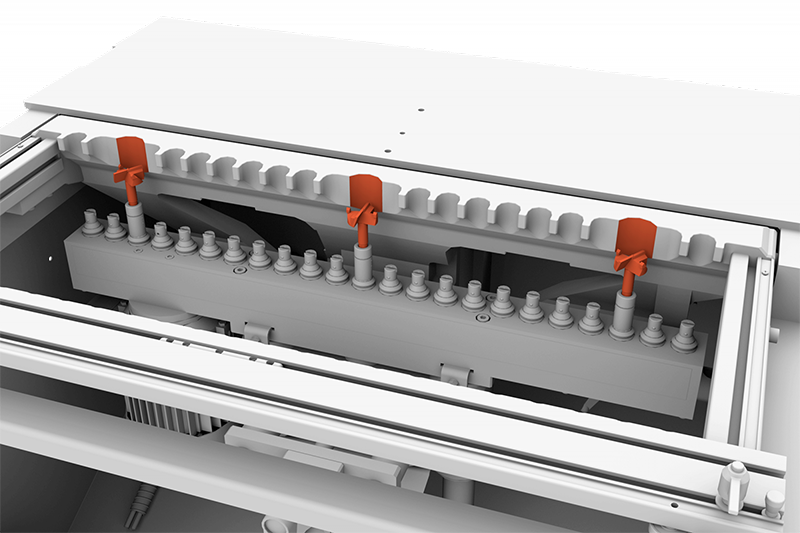

The comb has been designed so as to have 3 fixed positions where You can use cutter-drill bits of large diameter, without any further adjustment of the boring head.

FAST DRILLING OF HINGE HOLES

You can apply the boring aggregates of the available typologies ( BLUM, HETTICH, SALICE, GRASS) to drill the three hinge holes in one working cycle.

Semiautomatic, multispindle, single-head boring machine Maggi 21 PRESTIGE