Including €2.80 for ecotax

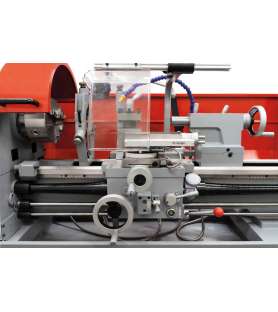

Reference: HED1000KDIG

Holzmann ED1000KDIG metal lathe specially designed for Holzmann ED1000KDIG metal lathe specially designed for the manufacture of tools and parts in training centers and schools, as well as in factories and workshops.

Totally secure payment!

Totally secure payment!

Be delivered where you want!

Be delivered where you want!

14 days to change your mind!

14 days to change your mind!

IMPORTANT FOR THE DELIVERY AND START-UP OF XXL MACHINES!

XXL machines are only shipped by 38 ton truck WITHOUT tailgate. The delivery location must be planned so that this type of truck can approach and maneuver easily. By ordering an XXL machine, the recipient undertakes to be equipped with a lift or other stacker in order to remove the machine from the truck themselves on the day of delivery. Any unsuitable or insufficient lifting means causing the machine to fall cannot be blamed on the carrier or the factory.

If access is impossible by this type of truck, the machine must remain at the carrier's depot close to the customer who will then organize removal by its own means (trailer, van). If the carrier has the possibility to offer delivery by smaller truck, the additional costs will be the responsibility of the customer and must be paid before delivery.

Getting started : The prices do not include assembly or electrical installation which must be done by a professional in order to avoid any damage to the machine's motors and electrical circuits that the warranty cannot cover.

Holzmann ED1000KDIG metal lathe specially designed for Holzmann ED1000KDIG metal lathe specially designed for the manufacture of tools and parts in training centers and schools, as well as in factories and workshops.