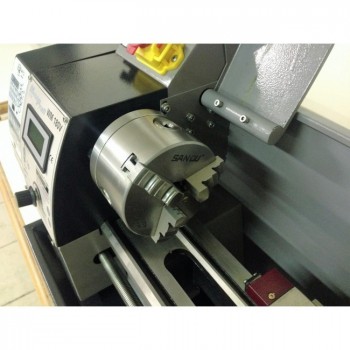

General description :

- With a built solid, this machine demonstrated excellent rigidity, even when machining of very hard steel

- Equipped of series with automatic feed longitudinal.

- Bench prismatic grey cast iron, tempered by induction and rectified with precision.

- Axis tempered with taper-roller bearings, adjustable.

- Spindle nose less than 0.009 mm ensures maximum accuracy of shooting.

- Rotation speed can be continuously adjusted, the speed can be easily read on the digital screen.

- Change of speed that allows a wide range of work.

- Powerful engine maintenance-free, with trigger.

- Power Transmission continues.

- The tailstock can be adjusted for shooting conical

- Cart upper swivel for turning conical

- Wide possibilities of threading through pine-treated steel

- You can perform the steps to the left

- Bearings guaranteed quality P6

- Sliding headstock with handle quick clamping and offset +/- 5 mm for turning conical

- Reverse rotation on the control panel

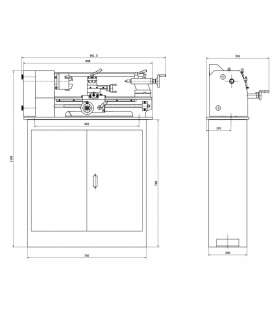

Technical characteristics :

- Motor power : 230V - 50 Hz - 600W

- Width of bench : 100 mm

- Height of spikes : 110 mm

- Entrepointes : 400 mm

- Ø machinable max. : 210 mm

- Spindle speeds : 50 - 2550 rpm

- Number of speeds : continuous Adjustment

- Morse taper of spindle : MT3

- Bore of spindle : 21 mm

- Bore of the chuck 3 jaws : 21 mm

- Linear travel of the carriage : 290 mm

- Morse taper of tailstock : CM2

- Race side of the slide : 80 mm

- Linear travel of the carriage : 85 mm

- Race cross table : 55 mm

- Race against edge : 60 mm

- Advances in longitudinal : 0.1-0.20 mm x tour

- Number of forward speeds : 2

- Metric thread : 0.5 - 3.0 mm

- Thread imperial : 8-44 TPI - 220 kg

- Dimensions : 830 x 480 x 370

- Weight : 70 kg

- Packing : 900 x 480 x 450 / 80 kg

Comes with :

Chuck 3-jaw chuck Ø100, fixed peak CM2, fixed peak CM3, carter for the protection of chuck, rear housing, chip tray, turret, 4-position, service keys, gears for metric and imperial thread

Totally secure payment!

Totally secure payment!

Be delivered where you want!

Be delivered where you want!

14 days to change your mind!

14 days to change your mind!