General description of the Bernardo Standard 150 Basic - 400V metal lathe :

Very practical machine with lead screw and turning bar for tapping and automatic feeding

Removable broken bench for machining large diameter parts

Massive ribbed prismatic bench to minimize oscillations

Simple, accessible and precise speed and feed adjustment controls

Heavily ribbed prismatic bench with induction hardened and ground slide

Tailstock offset of ±10 mm for machining tapered parts

Tailstock with clamping lever, crank with adjustable fine graduation (0.04 mm)

Sliding headstock, fixed headstock and all guides are adjustable

Graduated upper carriage (0.02 mm), swivel ± 45°

The Bernardo Standard 150 Basic - 400V metal lathe comes with :

3-jaw chuck DK11-160 mm / D4

Independent chuck 200 mm / D4, DIN 55029

Fixed bezel - maximum passage ø 60 mm

Mobile bezel - maximum passage ø 60 mm

Mounting flange 250 mm

4 position turret

4 position turret protector

Torque limiter

Micrometric longitudinal guide

Chip tray

safety cover

2 centering drills

Device to fall back into the step for threading

Reduction cone

LED lighting

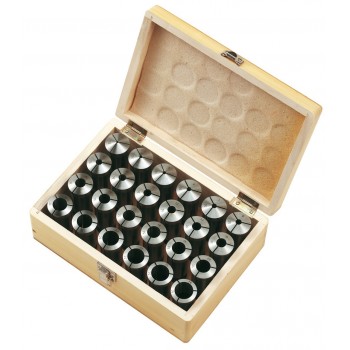

Interchangeable gears

CE standard magnetic brake motor

Basement

Service tools

Technical characteristics of the Bernardo Standard 150 Basic - 400V metal lathe :

Between points: 1000 mm

Tip height: 165 mm

Machinable diameter above the bed: 330 mm

Machinable diameter under the broken bed*: 430 mm

Machinable diameter above the carriage: 180 mm

Bench width: 180 mm

Spindle clearance: 40 mm

Spindle taper: DIN 55029, D1-4

Rotation speed range: (9) 75 - 1400 rpm

Longitudinal feeds: (40) 0.053 - 1.29 mm/rev

Transverse feeds: (40) 0.013 - 0.31 mm/rev

Metric threads: (32) 0.4 - 7 mm

Inch threads: (36) 4 - 60 tpi

Tailstock quill travel: 110 mm

Tailstock quill cone: CM 3

S1 100% continuous power: 1.5 kW (400 V)

S6 power 40% 2.2 kW (400 V)

Machine dimensions (L x D x H): 1600 x 700 x 1280 mm

Weight (approx.): 455 kg

* Length of removable broken bench: 220 mm

Reference

BSTANDARD150BASIC

In stock

100 Items