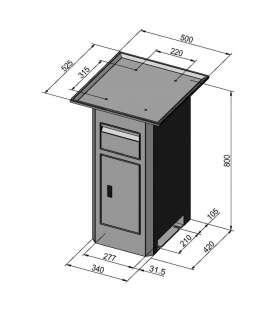

Base for Bernardo BF28BDC milling machine

€390.00

Tax included

Base for Bernardo BF28BDC milling machine

Including €2.80 for ecotax

Reference: BBF28BDC

Bernardo BF28BDC milling drill equipped with a direct current motor. The advantages are high torque in low speed ranges and almost constant speed under load. This model is suitable for professionals and modelers.

Totally secure payment!

Totally secure payment!

Be delivered where you want!

Be delivered where you want!

14 days to change your mind!

14 days to change your mind!

The machine is delivered without the base which is optional!

Base for Bernardo BF28BDC milling machine

Bernardo BF28BDC milling drill equipped with a direct current motor. The advantages are high torque in low speed ranges and almost constant speed under load. This model is suitable for professionals and modelers.