Including €2.80 for ecotax

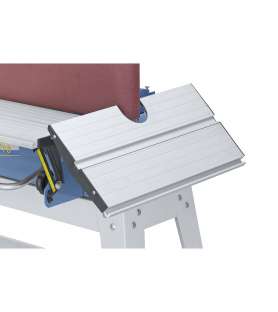

Reference: BHV70-230V

The Bernardo HV70 belt sander allows you to work high, wide and long pieces thanks to its sanding stop.

.png)

Before starting, always check the inside of your machine, see if the belts are fitted correctly, tighten the bolts, etc... because the various transports cause vibrations.

Always use a 2.5² wire size extension cord

The extension cord must not exceed 10 meters and must not be rolled up

The use of drums, triplets or multi-plugs is PROHIBITED

Have a standard electricity meter with neutral and earth

Always work with a chip extractor for your health and for the guarantee of the machine

Always grease cast iron tables with wood glider

Always work with guards in place

Do not work with blunt or blunt tools as this may damage the internal mechanism.

The Bernardo HV70 belt sander allows you to work high, wide and long pieces thanks to its sanding stop.